Misting Pump Demo: How PSI Affects Droplet Size [VIDEO]

Shawn Glover, VP of Sales, Feb 14, 2023

![Misting Pump Demo: How PSI Affects Droplet Size [VIDEO]](https://www.pumptec.com/hubfs/images/blog/Misting-Pump-Demo.jpg)

No one likes spitting and sputtering, especially in a high-pressure misting system.

In our testing facilities here at Pumptec, we’re able to test each commercial misting pump unit that goes out the door to ensure it performs as promised and produces proper droplet sizes. In our latest video, we tested a pump to demonstrate the major differences between two PSI settings on a misting system and why maintaining proper PSI is so important. Take a look.

MISTING PUMP DEMO VIDEO TRANSCRIPT:

We’re in the Pumptec engineering lab demonstrating spray droplet size with a mist nozzle. We have a 113C pump with a:

- Primer bulb

- Inlet filter

- Discharge hose

- Regulator assembly

- Digital pressure gauge (to adjust the PSI)

- Bypass valve

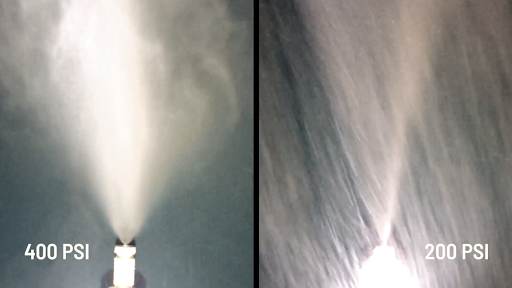

Start the pump and close the bypass valve to send pressure out to the nozzle. The nozzle is fastened to a frame with LED lights shining up into the mist, and a camera mount nearby. When I change to 400 PSI and turn the lights off, you can see the mist droplets are very small. At 200 PSI they are larger and fall back down onto the lights.

FEATURED PUMP: 113C Series Misting Pump

Additional Misting Pump Considerations Beyond PSI

The final results between 400 PSI and 200 PSI are quite dramatic, as shown in the final image from the video.

Misting pump demonstration showing droplet size at 400 PSI and 200 PSI

However, there is more to consider than a pump’s PSI. Gallons per minute (GPM) and nozzle size play crucial roles, as does the pump’s performance and output.

GPM: Pressure is produced as a result of resistance to flow, typically created by the nozzle. As we’ve noted in our previous article on flow vs. pressure, without flow, there is no pressure. So, ensuring adequate GPM is crucial.

Misting Nozzle Size: Depending on the job at hand, misting nozzle orifices typically vary between 0.1mm and 0.3mm. The small orifice helps to regulate the fluid’s capacity and water droplet size exiting the nozzle.

RELATED: Spray Nozzle Selection Chart and Calculator

Consistent Output: If the pump’s flow output is inconsistent or pulses as it cycles, fluid will be forced through the nozzle at varying pressures. When the flow drops, the pressure also falls and results in larger droplets.

Why Consistent Misting Droplet Size Matters

Variations in droplet size may not be of much concern when broadcasting over a large area. Some industries, however, are highly regulated and require precise droplet sizes and application rates.

RELATED: Misting vs. Fogging: What’s the Difference?

Dust suppression equipment used in construction is one example. The system must produce a mist that is fine enough to encapsulate and reduce airborne particles and silica crystalline dust to below 50 micrograms per cubic meter, per OSHA standards. Inconsistent flow will result in pressure spikes followed by sudden drops in pressure, resulting in varying mist droplet sizes.

Too fine of a mist may not suppress the dust to acceptable levels, while too heavy of a mist will result in water droplets falling to the ground and creating wet surfaces. Wet surfaces are of great concern when used near electronic equipment and can be a major slip and fall hazard.

CASE STUDY: Dust Curtain for Concrete Grinding Tool Manufacturer

Other highly regulated industries that use misting pump systems are disinfection and pest control. Disinfectants and pesticides must be applied at consistent rates to ensure the safety of operators, their customers, pets, and livestock. Likewise, pump materials must be compatible with the chemicals used or risk premature pump failure.

Best Misting Pump Type

One of the most important criteria when selecting a misting pump is ensuring it is a positive displacement pump, such as a plunger pump. Positive displacement pumps can deliver the higher pressure necessary for misting applications.

Some operators use diaphragm pumps, but the problem is that they have flexible components that inherently produce varying flow. This makes them unsuitable for precise applications or those that need to comply with strict regulatory requirements. The flexible components are also prone to wearing out quickly. Diaphragm pumps may also require the use of gas power to produce adequate flow due to their inefficient operation, making them loud, bulky, and too costly for many misting environments when factoring in total cost of ownership.

RELATED: Pump Comparison: Diaphragm Pumps vs. Plunger Pumps

The ideal misting pump is a high-pressure plunger pump. Plunger pumps have rigid components that deliver fixed flow rates, ensuring consistent droplet sizes in misting applications. Plunger pumps are more durable, ensuring long-lasting performance, and are also more compact and efficient, allowing for battery operation with ample run times.

One of the reasons plunger pumps are so efficient is because of their simpler design, which also has the side benefit of requiring less maintenance. That said, all pumps still require some maintenance to ensure a long life. So, be sure to check out our Pump Maintenance Checklist below.

If you’re looking for the ideal pump to configure into your misting system, contact our team of engineers. We’ll help you pinpoint your needs and deliver a pump system to your exact specifications.