Top 5 Features in Professional Lawn Care and Pest Control Pumps

Shawn Glover, VP of Sales, Mar 8, 2022

A beautiful lawn and a landscape free of pesky insects is the key to enjoyable events, activities, and backyard living. Achieving that goal safely and efficiently isn’t always easy, which is why professional lawn care and pest control technicians require proper equipment to get the job done right.

Landscapers and lawn care professionals need to consider the following features when choosing which pump to use in their sprayers.

Top High-Pressure Pump Features to Look For in Lawn Care and Pest Control

1. Chemical Compatibility

Chemical compatibility is one of the most crucial aspects of pump performance. So what are commonly used chemicals in lawn care and pest control?

Common Chemicals in Lawn Care

Fertilizers used for lawn care typically contain nitrogen, phosphorus, and potassium (NPK). Used properly, these nutrients can create a lush lawn and show-stopping landscapes. Overapplication, however, is directly linked to groundwater contamination and excessive weed growth in lakes and streams. The EPA reports that the majority of wildlife poisonings are a result of improper use of lawn chemicals.

On the flip side, herbicides kill plants such as crabgrass and broadleaf dandelions. There are a host of chemicals in this category and caution should be taken when applying them, ensuring that no overspray occurs. Glyphosate — commonly referred to as RoundUp® — is a sometimes controversial chemical that is non-selective, meaning it will kill all vegetation, and is linked to some forms of cancer. Pre-emergent herbicides prevent seeds from germinating while selective herbicides are formulated to kill only select types of grasses and weeds.

Common Chemicals in Pest Control

The most common chemicals used for pest control sprayers are Pyrethrins. These compounds are derived naturally from chrysanthemums which are toxic to most insects. They are especially effective against mosquitos in addition to many other household pests. Pyrethroids are a synthetic version. While generally considered safe for pets, agricultural animals, and humans, both can be extremely toxic to aquatic life. Minimizing runoff and overspray is critically important to help maintain a balanced ecosystem.

Another common pest control chemical is Fipronil, a broad use insecticide used to kill termites, fleas, ticks, roaches, and various beetles by disabling their central nervous systems. Unlike Pyrethrins which kill insects by direct contact, Fipronil works by direct contact and ingestion, and it can be taken back to a nest to help to kill an entire colony. Care should be taken when applying Firponil as it has the potential to be toxic to humans and animals.

Pump Material Considerations

Because of the wide range of chemicals used in the lawn care and pest control industries, it can be difficult to find pump materials that are compatible with them all. In general, look for a pump with stainless steel or ceramic plungers and aircraft-grade anodized aluminum heads. Both have A ratings for insecticides and fertilizers.

Selecting pump materials involves more than just internal components and housing; it’s also important to consider which type of elastomers and seals to use. We recommend the use of Viton o-rings vs. Buna. Viton seals are more resistant to the hydrocarbons often used in agricultural chemicals.

Typically, the same pump can be used for multiple applications by simply flushing the system before converting to another tank.

2. Pump Flow and Pressure

All those chemicals have strict regulatory requirements that designate proper application rates. Without the right combination of flow and pressure, a pump operator won’t be able to maintain an accurate spray pattern or have enough vertical throw to reach the eaves of a house. Improper flow and pressure means they’ll need to make multiple passes and potentially use more chemicals than necessary. Of course, the types of nozzles being used are another critical factor.

An understanding of fluid dynamics is critical when designing a pump. While ensuring a pump is durable enough to withstand high pressure, the amount of flow in combination with the proper nozzle is what dictates proper coverage.

In general, lawn care pump sprayers require higher flow and less pressure (up to 6.8 GPM and 300 PSI) whereas misting pumps used for mosquito control require lower flow and higher pressure (.25 GPM and 1000 PSI).

When precision is important, the use of plunger pumps is ideal due to their consistent output and performance.

3. Compact Size and Pump Portability

Getting operators in and out of jobs quickly can be the difference between profit gains or losses, making electric pumps ideal. Electric pumps are smaller and much lighter than gas-powered pumps, making it easier for them to be mounted as part of a boom sprayer or mobile application.

Many mosquito control systems are fixed units that are stationed around a property, such as a golf course or yard. They’re typically automated to turn on for a couple minutes just before dawn and again before dusk when mosquitoes are most active. These units benefit from a compact pump size from both an aesthetic and functional aspect.

4. Pump Amperage

Drawing too many amps with a pump can be an issue for tractor equipment that doesn’t have an alternator to recharge the battery and, instead, uses a magneto. Too much amperage can quickly drain a battery. The key is to maintain consistent flow and pressure at lower amps.

Depending on the application, we recommend a pump that draws up to 30 amps. However, not all pumps can deliver enough flow and pressure at lower amperages, so it’s critical to address this issue with a pump engineer.

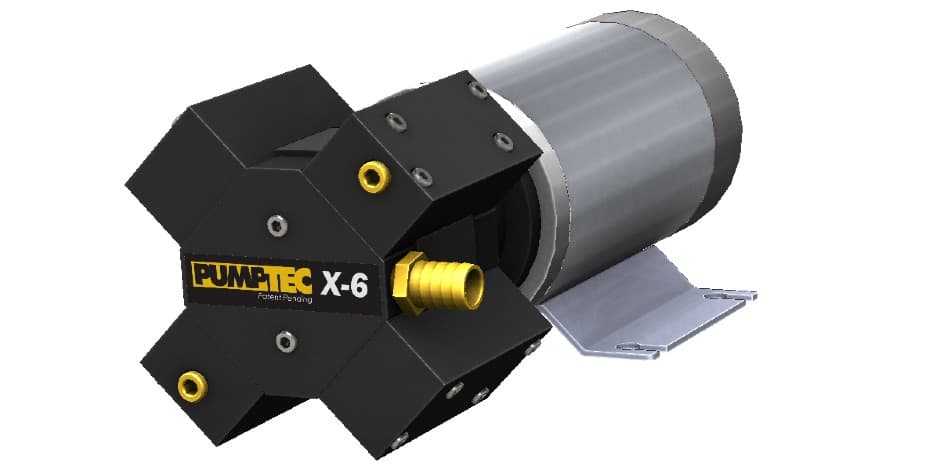

FEATURED PUMPS:

Our 12V DC motor 350U plunger pump was designed specifically for the pest control industry, delivering 2.6 GPM and 300 PSI at 30 amps.

Our X-Series plunger pump also features a 12V DC motor drawing 30 amps and delivers up to 6.8 GPM and up to 300 PSI for greater horizontal and vertical throw.

5. Sustainability

A major concern among consumers who use professional lawn care services is the impact on the environment. While the proper chemical application rates are certainly top of mind, many also scrutinize the use of fossil fuels and a company’s carbon footprint. This is an area where electric pumps shine due to their use of rechargeable battery power. Additional measures of pump sustainability might also include whether it was made in the U.S.A and its overall longevity. A durable, long-lasting pump is less likely to end up in a landfill.

Another concern among many neighborhoods is noise pollution. Some communities have restrictive noise ordinances, requiring quieter operation than what might be possible with gas-powered sprayers. Electric-powered lawn care sprayers are ideal for keeping noise decibels to a minimum and are a common courtesy to homeowners and residents.

RELATED: What You Need to Know About Pump Noise Levels and Causes

Choosing the Right Pump for Your Application

Because of the numerous types of applications a pump operator might need to perform on a given job, versatility becomes a top priority. For example, an operator may mount a boom sprayer to a small piece of equipment to spray weeds, but may not be able to reach certain areas. The ability to turn a ball valve to switch to a spray gun becomes important in this situation.

Proper plumbing configurations that allow for such functionality allow operators to get in and out of jobs faster and also saves costs because they don’t have to invest in multiple pump systems. Our 114 pump delivers in this area.

Choosing the right pump comes down to the goals a company wishes to achieve. The pest control company, Terminix, for example, wanted to reduce their use of fossil fuels and improve performance and mobility. They switched from a 250-pound, 5 HP gas engine to an electric X-Series pump that weighed less than 75 pounds without compromising power or output. Be sure to read their full case study below.

When selecting which pump manufacturer to use, consider the benefits of a custom pump solution that addresses the numerous requirements of your application. You might be surprised how economical and effective the results may be. Reach out to the pump experts at Pumptec to explore the possibilities today.

![Choosing the Right Spray Nozzle for Commercial Cleaning Pumps [VIDEO]](https://www.pumptec.com/hs-fs/hubfs/images/blog/pressure-pump.jpg?width=300&height=200&name=pressure-pump.jpg)