Reduce Operating Costs With the Right Portable Sanitation Pump

Shawn Glover, VP of Sales, Apr 11, 2023

To reduce operating expenses, business owners often look to improve efficiencies, minimize downtime, and reduce labor costs. Leveraging new technology and equipment often tops the list of potential solutions.

For years, there was little change in portable sanitation pump technology. Now, Pumptec’s X-Series washdown and fill pump system is revolutionizing the portable sanitation industry by helping operators streamline their operations in several ways.How can you tell whether the Pumptec X-Series pump will reduce operating expenses for your portable sanitation business? Calculate the following cost factors.

RELATED VIDEO: Portable Sanitation Wash Down Pump Considerations

Labor Costs

One of the best ways to reduce labor costs is to get jobs done faster, allowing operators to service more customers in a day to maximize profit margins. The challenge is doing so while still providing optimal cleanliness.

The powerful Pumptec X-Series plunger pump system delivers consistent, reliable pressure up to 300 PSI. When equipped with a spray gun and a high-pressure nozzle, operators can wash down a portable toilet quickly and effectively without having to use rags or brushes. With the addition of a ball valve and a quick disconnect, operators can switch to fast-fill mode and fill a tank at 6.8 GPM.

In our real-world field tests, operators report that the dual-purpose X-Series pump system saves them a minute or more per house because they can wash down and fill with a single pull from the truck. They also feel less fatigued at the end of the day, helping to improve employee productivity and satisfaction.

Potential Labor Cost Savings

Reducing the time spent washing down and filling each portable toilet by one minute on a 100-house daily route can save one hour and 40 minutes. To estimate potential cost savings, calculate the hourly salary savings per employee on the route. Additionally, consider the higher profit margin per customer and additional revenue from being able to add more stops.

Environmental Costs

A consequence of insufficient knock-down power is that an operator inevitably uses more water attempting to clean each unit. This can deplete the reservoir tank too quickly and not leave enough fresh water to clean and fill other units and handwashing stations. Operators end up having to drive back to the shop to refill their tanks more often than necessary to complete their routes.

Reducing water waste and fuel consumption is both ethical and economical. Plus, customers may prefer a business that demonstrates efforts to reduce their carbon footprint. Promoting your green initiatives can help differentiate your portable sanitation business from others.

Potential Environmental Cost Savings

Calculate how much you can save on fuel costs, labor, and other expenses as a result of fewer trips back to the shop. Also consider potential revenue generated from customers who respond to your promotions as a more sustainable option than the competition.

Pump Maintenance Costs

Truck-mounted portable sanitation pump systems need to be protected from excessive vibration and shock resulting from road conditions and the elements. Harsh environments call for pump systems made from durable, high-tensile-strength materials.

RELATED: Pump Installation Tips for Portable Restroom Trucks

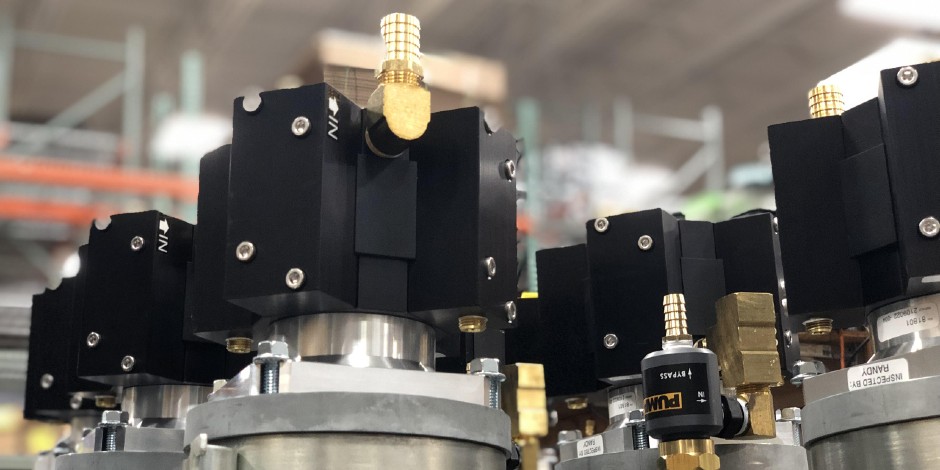

Pumptec X-Series pumps are crafted from aircraft-grade anodized aluminum with ceramic plungers and stainless steel valves and are nearly indestructible. Because they feature sealed bearings, internal components are less prone to exposure to the elements and don’t need daily lubrication or oil checks. As a battery-powered unit, they have a simpler design than gas-powered pumps and require much less maintenance. In the end, there’s less that can go wrong.

Potential Maintenance Cost Savings

Over time, maintenance costs for gas-powered engines or those made from inferior materials can add up significantly. While it’s difficult to accurately predict cost savings of maintaining and operating the X-Series electric-powered plunger pump compared with similar units, it’s safe to say that it will experience far fewer breakdowns and require fewer repairs over time.

RELATED INFOGRAPHIC: Compare Electric vs. Gas-Powered Pump Systems

Portable Sanitation Pump Costs vs. Value

Like many technologies, portable sanitation pumps vary significantly between manufacturers, as does their cost. When comparing one pump with another, it’s easy to be swayed by a product’s upfront costs. Operational costs over time, however, can quickly erode any “savings” that might be reflected on a pump manufacturer’s invoice.

It’s critical for portable sanitation operators and equipment manufacturers to take a holistic approach and calculate the total cost of ownership. A slightly larger investment up front can drive long-term value and dividends by way of reduced labor, environmental, and maintenance costs.

What can be difficult to calculate are the intangible costs of doing business including the frustrations and stress associated with using inferior equipment. The pump experts at Pumptec can help with that, too. Contact us today to talk through your portable sanitation pump requirements. We’ll customize a solution that’s tailored to your needs and delivers on its promises.