Features to Look for in Desalination & Reverse Osmosis Pumps

Shawn Glover, VP of Sales, Jan 31, 2023

For those who sail the high seas on sailboats and yachts, reverse osmosis pumps and watermakers can be one of their most critical pieces of equipment. Desalination pump failure while out at sea could pose a life-threatening situation without enough potable water.

Turning seawater into drinking water is not an easy feat, however. Saltwater is inherently corrosive and can quickly degrade pump materials if not properly engineered. How do desalination pumps work, and what features should owners or manufacturers of cruising vessels look for?

How Desalination Pumps Work

Desalination occurs through a process called reverse osmosis. A water maker pump system draws up water from the sea and forces it through multiple filters to remove sediment and particulates. It then sends the clean water through a reverse osmosis membrane at high pressure to make it potable.

The types of membranes and filters used as part of a system should be of the highest quality and replaced at intervals according to the manufacturer’s specifications to ensure maximum output and durability.

Even though the concentration of salt in seawater is only about 3.5%, the majority of water that passes through the desalination system (about 90–95%) is considered wastewater and returned to the sea. The other 5–10% is captured as drinking water. Why such low output? The system isn’t just filtering out salt; it’s also filtering out bacteria, sand, and other particulates to deliver only fresh, potable water.

VIEW RELATED CASE STUDY: Reverse Osmosis — Goin’ Off the Grid

Ideal Reverse Osmosis Pump Features

The type of pump matters just as much as the proper filters and membranes. There are numerous differences among reverse osmosis pump manufacturers, with some intended for large or small output.

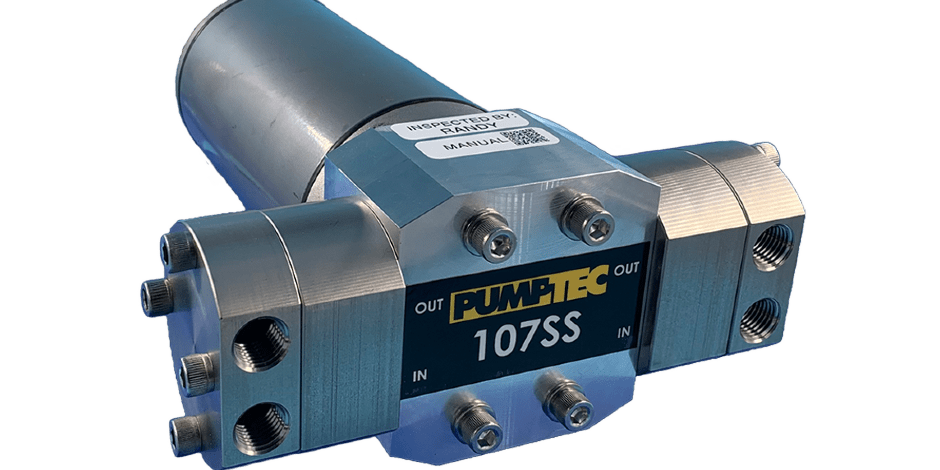

In particular, the Pumptec 107SS reverse osmosis pump (formerly known as the 116C) is ideal for vessels with fewer than five people. The pump can produce up to 30 gallons of clean water each day. Due to its compact size, some captains use two pumps to deliver twice the volume or have one to serve as a backup unit.

Because the 107SS is a self-priming positive displacement plunger pump, it doesn’t need a feed pump even when mounted above the waterline. Plunger pumps deliver consistent flow and pressure even with movement from waves or wake. Additionally, operators report that the pump can sit unused for long periods of time and start without issues. Delivering consistent flow and pressure up to 1000 PSI, the 107SS pump actually embeds solids deeper into the membranes, resulting in longer membrane life.

There are numerous other features to consider when selecting a pump for desalination, and some you may not have thought of.

Pump Materials

Seawater mostly consists of sodium chloride — the chemical name for common salt. Concentrations of magnesium chloride, calcium chloride, and other elements are also found. These chemicals can quickly corrode a pump body and its components if not made of compatible materials.

The best material for reverse osmosis pump bodies and valves is marine-grade stainless steel, which is incredibly strong and doesn’t degrade when exposed to seawater. Unlike commodity pumps made in China, the bodies of our 107SS pumps are machined from solid bars of stainless steel right here in Minnesota with the highest tolerances.

Plungers should be constructed of ceramic. When operators hear the term “ceramic,” there’s an assumption that it is a delicate material. However, ceramic plungers are highly durable in desalination systems. Look for solid ceramic plungers rather than ceramic coated. The Pumptec 107SS is made from solid alumina ceramic which has a highly polished, smooth, non-porous finish. Viton® or Buna® o-rings help provide a proper seal.

Pump Size

Space is a premium on most sailboats and cruisers. Achieving a compact size and weight while still delivering enough power is a concern for many operators. The 107SS is the smallest 1000 PSI desalination pump on the market.

Pump Noise

One of the pleasures of sailing is the absence of engine noise and gas fumes. The 107SS pump has a very low decibel rating with a quiet, consistent hum, allowing the sounds of the wind, sea, and marine life to take center stage.

Pump Efficiency

Amperage draw is a major consideration when selecting a reverse osmosis pump. The available power on many sea vessels is limited and needs to be preserved as much as possible. The 107SS pump runs on a 12V system and is the most efficient on the market, drawing only 10–13 amps. Compare this to most other desalination systems that draw three times the power, between 30–50 amps.

RELATED ARTICLE: The Critical Importance of High-Pressure Pump Efficiency

Solar Capabilities

On the heels of efficiency is a pump’s ability to be solar-powered. Low amperage draw on vessels that are equipped with solar power helps to conserve energy for other critical functions like navigation systems.

Pumptec’s 107SS pump can be easily configured into reverse osmosis systems, especially with the help of our expert design and engineering team. They can customize a plug-and-play system that is reliable, efficient, and rugged enough to withstand the sea’s harsh conditions, delivering peace of mind and lower total cost of ownership over time.

Contact our team of pump experts today to explore integrating the 107SS Pumptec pump into your reverse osmosis system, and remember to check out our helpful case study below featuring a solar-powered reverse osmosis system.