Choosing the Right Spray Nozzle for Commercial Cleaning Pumps [VIDEO]

Shawn Glover, VP of Sales, Oct 26, 2021

![Choosing the Right Spray Nozzle for Commercial Cleaning Pumps [VIDEO]](https://www.pumptec.com/hubfs/images/blog/pressure-pump.jpg)

A lot of time, effort, and money go into selecting the right high-pressure pump for an application. The type of pump material, plumbing configurations, self-priming functions, chemical compatibility, and its flow and pressure rating are all major considerations to make sure you’re getting the performance you need for your commercial cleaning application.

Then along comes a decision about a seemingly small and relatively inexpensive component that can change everything: the nozzle.

If you use the wrong nozzle, you’ll not only get disappointing cleaning results, you might actually damage the surfaces you’re trying to clean or damage the pump itself.

How do you determine the right nozzle size? First, let’s cover the basics.

What Do Spray Nozzle Numbers Mean?

High-pressure cleaning nozzles have numbers assigned to them that indicate how they will perform. But what do the numbers mean and how do you choose the best nozzle to achieve the results you want?

There are typically four or five numbers stamped on a nozzle. The first two digits typically identify the angle or degree of the spray pattern. The last one or two digits on a nozzle indicate the size of the orifice (opening) the fluid needs to pass through. If the number ends in 35, that indicates that the nozzle size is 3.5, for example.

The smaller the number, the smaller the orifice and the more restricted the flow. This restriction, in turn, creates built-up pressure and a stronger stream of fluid. Imagine a garden hose with an adjustable nozzle: the more you tighten the nozzle, the smaller the opening becomes, allowing more pressure to build up and creating greater force of the water coming out the end.

The shape of the orifice also makes a difference and will produce different spray patterns for use in various applications. A softwash application may require a fan spray pattern with a slightly larger orifice to achieve enough flow or output. As such, you’ll need a pump with a higher GPM rating to achieve the vertical throw needed to reach the eaves of a house, for example. However, a steam cleaning nozzle for a carpet extractor or hard surface cleaner will have a small orifice with a round pattern that produces a fine mist and very limited output. This type of application will require a high PSI rating but a lower GPM rating than the softwash application.

Some nozzles also are color-coded, with the various colors identifying the fan pattern in degrees. Red is 0 degrees, yellow is 15, green is 25, and white is 40.

Getting Started — Spray Nozzle Chart Calculation

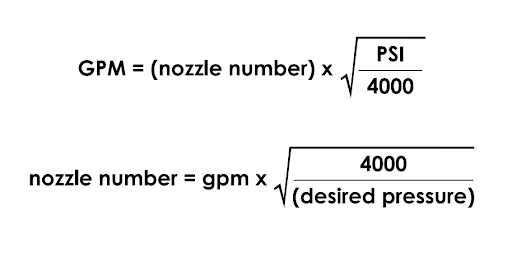

The formula for calculating the performance of a spray nozzle can be confusing to some. The formula looks like this: If you’re not a math whiz, building your own interactive spray nozzle performance chart can be done relatively easily with a little Excel spreadsheet know-how and your pump’s GPM and PSI rating in hand. The video below shows a step-by-step method for creating a nozzle performance chart for your high-pressure pump.

If you’re not a math whiz, building your own interactive spray nozzle performance chart can be done relatively easily with a little Excel spreadsheet know-how and your pump’s GPM and PSI rating in hand. The video below shows a step-by-step method for creating a nozzle performance chart for your high-pressure pump.

ALSO WATCH: Pump Spray Nozzle Selection Chart & Calculator [Video Pt. 2]

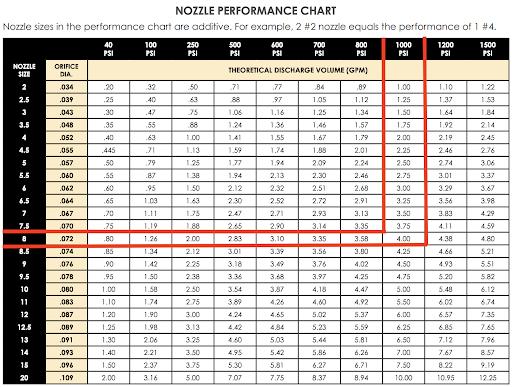

Using the method outlined in the video can help you determine the optimal nozzle for your specific application. Quality pump manufacturers will help do some of the work for you by providing several predefined calculations that align with their pump products. Before taking the step of doing your own calculations, check out the Pumptec nozzle performance chart on page 4 in the Pumptec Engineering Guide.

Example: If your pump’s PSI is 1000 with a GPM rating of 4, you’ll want to select a #8 nozzle.

The Importance of Choosing the Right Nozzle

Once you find the right-size pump for your application, you’ll need the right nozzle. Choosing the wrong nozzle could result in serious consequences.

A spray nozzle that produces too powerful of a blast could strip paint from surfaces, damage mortar, or force fluids behind siding or shingles, causing water damage. Surfaces aren’t the only thing that can sustain damage; there are thousands of people who end up in emergency rooms every year with injuries sustained by sprayers that are too forceful for an application or from hoses that rupture or detach from equipment. The pump itself could also be damaged if too much pressure builds up repeatedly from using the wrong nozzle, straining the motor and causing it to fail prematurely.

It’s amazing how something so small can make or break your pump’s performance. While finding the right nozzle is important, it’s still the pump that will ultimately determine success or failure. There are a lot of misconceptions about pump flow rates and pressure. Some people believe that they need a more powerful pump with a higher PSI rating to achieve the output they desire. Often, however, they actually need less pressure and more flow.

It all depends on your application. To see recommendations for various applications including commercial cleaning, agriculture, misting, chemical injection, and more, download our complimentary Guide to Proper GPM and PSI below. As always, reach out to our pump experts for further guidance or to request a free pump consultation.