Unloader Valves vs. Regulator Valves: What’s the Difference?

Shawn Glover, VP of Sales, Nov 10, 2020

The mechanics of many electric pump sprayers are pretty straightforward, but there are often questions surrounding whether to use an unloader vs. regulator valve in a pump system. This seemingly small component can make a major difference in your pump performance.

Plunger pumps, like most positive displacement pumps, require a pressure regulating device in the high pressure discharge line. Without one, the pump will keep pumping until the pressure builds to dangerous levels resulting in a ruptured discharge line or a blown motor fuse. You can choose between a regulator or a pressure regulating unloader, but choosing to go without anything is unsafe and not an option.

So, should you use a regulator valve or an unloader valve? Like many things in life, the answer is, “It depends.” It all comes down to your application and intended use. Here, we’ll break down the difference between an unloader and a regulator to help you make the best choice.

Regulator Valve Explanation

What is a regulator valve? Pressure regulator valves maintain a set maximum pressure in a system as a result of bypassing fluid. The system pressure may be lower at different times as valves open and close, but the pressure will not exceed the maximum set pressure.

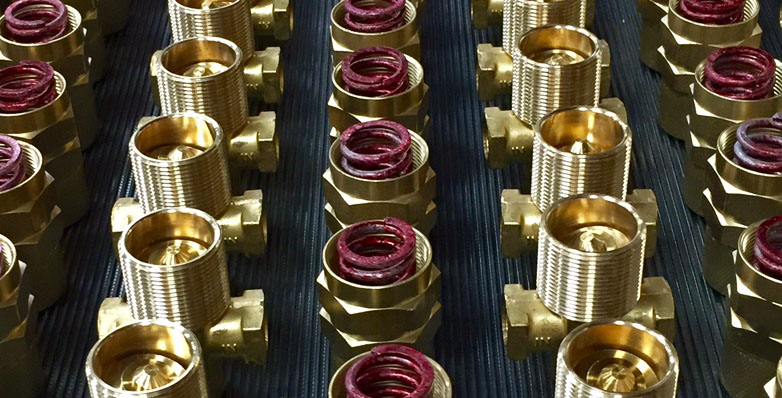

In general, regulator valves are less expensive and they’re easier to design into a system. That’s because they’re simple devices that typically consist of a piston or ball held on a seat by the force of a spring. The force created by system pressure on one side of the piston needs to be greater than the spring force on the opposite side of the piston before the piston will begin to move and release fluid. The piston will move to release only the fluid necessary to maintain the system pressure.

Common uses of water pressure regulator valves include applications where low flow is required. Some examples include ultra-fine misters for greenhouses, evaporative cooling, and dust suppression. Pressure regulator valves are also used where precise application is required, as with disinfection sprayers and carpet extractors.

If you choose an unloader instead of a regulator valve, a build-up of pressure can occur between stops and starts and result in a burst of excess fluid at a higher PSI when the trigger is engaged. In the case of disinfection sprayers, it could result in inconsistent spray coverage, and a carpet extractor that uses an unloader instead of a regulator could end up with a puddle of excess water and cleaning solution on the floor.

Unloader Valve Explanation

What is an unloader valve? Pressure-regulating unloader valves provide the ability to control pressure similarly to regulators, but their special function is decreasing pump head pressure to very low PSI values when the valves are closed. This ‘no load’ pressure decreases wear on the pump and lowers energy consumption over time. Unloaders are more complex than regulators and have more moving parts, meaning they are more difficult to engineer into a system and can cost more.

These valves typically include a check valve in the discharge fitting that ‘traps’ pressure between a control valve, like a spray gun trigger, and the unloader. Inside the valve will be a piston and seat held down by a spring. The trapped pressure is greater than the spring force causing the piston to move and bypass fluid to flow. While this trapped pressure is maintained, the pump head pressure will be low. Once the valve is opened and the trapped pressure is released, the pump head pressure will return. It is very important with unloaders to have no leaks or loss of trapped fluid between the valve and unloader.

While no pump motor should be run continuously under bypass (letting go of the trigger for extended periods), an unloader valve can withstand longer bypass times and help mitigate overheating of a system, especially in high-pressure pumps. Continual bypass of fluids can cause the liquids to heat up or excess pressure to build up under high PSI if not ‘unloaded.’ Not only can certain fluids become dangerous at extreme temperatures, but the heat can damage rubber seals and other internal parts.

By far, the most common use is as a pressure washer unloader valve. They’re also found in irrigation systems, car washes, and other high-pressure applications that may require starting and stopping but aren’t too concerned about precise spray patterns. Unloaders may malfunction and pulsate if the flow rate is too low because the internal valve mechanism ends up shifting back and forth to compensate.

Reasons to Choose a Regulator Valve

As mentioned, if your application requires consistent and precise flow and PSI for misting sprayers, pest control, disinfection sprayers, and the like, you’ll want a pump with a regulator valve. They’re also great for applications with low flow rates. Additional reasons to use a regulator valve are:

- Simplicity of design for lower maintenance

- Use of a DC motor with shorter bypass times

- Strong chemical use

Reasons to Choose an Unloader Valve

Applications requiring high PSI and flow rates are ideal for unloader valves because they allow for more starts and stops without overheating. Additional considerations and applications include:

- Use of motor with longer bypass times

- Energy-sensitive applications

- Not concerned with ultra-precise spray patterns

Many find it confusing to decide whether to use an unloader or regulator in their equipment, especially if there’s uncertainty over the anticipated flow rates and PSI. Checking out our Guide to Proper GPM and PSI below might help clear things up. You’re also welcome to reach out to our team of pump experts to talk through your unique application. We’re happy to help you determine the right kind of valve and pump that will deliver the results you need.