Find the basic make up, common issues, and best practices for constructing a desalination system.

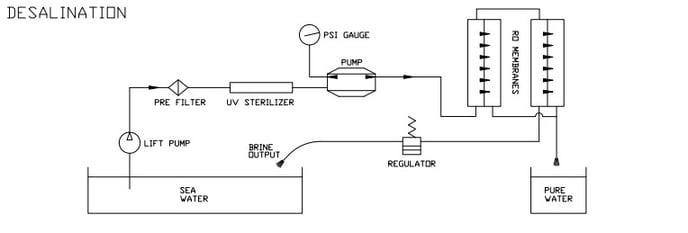

Shown above is a simple diagram for building a desalination unit. In the image you can see our pump pulls water from a supply tank through using a lift pump, a filter, and UV sterilizer. The fluid is then sent out one of two outlets. The first outlet monitors pressure and second sends the fluid through RO membranes. If the water is sufficiently clean, it exits the system as pure water. The unclean fluid cycles back through a regulator and back into the sea water tank. The regulator controls the pressure and can be adjusted. Please adhere to the following do's and don't's:

Shown above is a simple diagram for building a desalination unit. In the image you can see our pump pulls water from a supply tank through using a lift pump, a filter, and UV sterilizer. The fluid is then sent out one of two outlets. The first outlet monitors pressure and second sends the fluid through RO membranes. If the water is sufficiently clean, it exits the system as pure water. The unclean fluid cycles back through a regulator and back into the sea water tank. The regulator controls the pressure and can be adjusted. Please adhere to the following do's and don't's:

Firstly, the pump you use matters. Your system needs to hit a certain pressure and flow, please visit this page to view Pumptec's options based off of your needs. Pumptec's 107 Stainless Steel pump is a common choice for desalination systems. Second, the pump needs enough water. Do not run the pump dry, make sure your hoses are properly sized, and all connection points are water tight. We typically recommend using 1/2" S-hose to feed pump inlets, Pumptec pulse hose for pressurized outlets/sections of the system, and 3/8" to 1/2" S-hose on by-pass lines. These hoses keep great shape and allow enough flow. Starving the pump will lead to cavitation. These hoses easily connect with the needed strainers and filters between tank and pump.

Once the fluid leaves the pump, it is imperative to use a dampening hose. At Pumptec, 3/8" pulse hose is widely used. Because of the high operating pressure and the nature of our plunger pumps, the outlet hose type is extremely important to functionality. Be sure to always double check that your inlet and outlet hoses do not get pinched or damaged so as not to overpressure or run dry. Do not run your by-pass line from the regulator directly back to the pump as this could contribute to cavitation and overheating. Run it back to the solution tank as shown in the diagram above. Over-pressuring can also result from the incorrect regulator pressure limit. Pay attention to your gauge, so you do not over-amp your motor or over-pressurize your pump.

To reiterate, avoid starving or running the pump dry, pinched lines, incorrect pressure limits or pressure spikes, overworking the motor and/or pump, and overheating your water, pump and/or motor. Avoiding negative head pressure is also preferrable - this means that the supply tank the pump is drawing from is placed above the pump. One last thing to look for is a dysfunctional nozzle - they may be damaged, worn out, or clogged.

Normal check ups and maintenance checks are recommended on all pumps, hoses, fittings, and nozzles. Below are a few helpful links on pump maintenance, carpet extractors and the pumps on our website.

Helpful Links:

Desalination Pumps: Why Pump Efficiency & Solar Capabilities Matter

Choosing Chemical Resistant Pumps for Commercial Industries

Understanding Pump Flow Rate vs. Pressure and Why it Matters